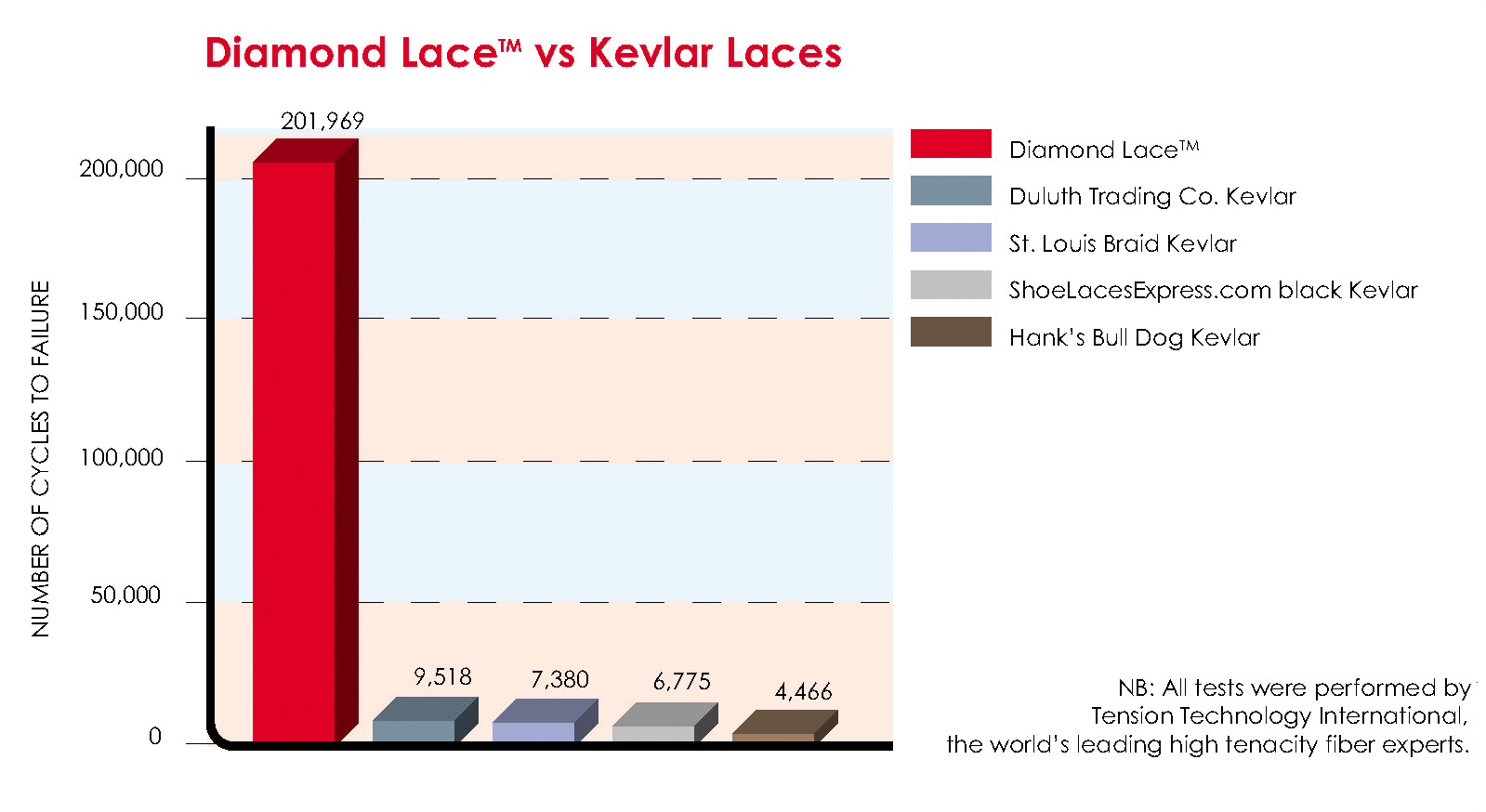

diamondlace™ testing

Comparison testing of diamondlace™ and other boot lacesThe tests were conducted by Tension Technology International (TTI) on the diamondlace™ boot laces, on four conventional boot laces and on four Kevlar boot laces. The tests were performed by drawing these laces back and forth through a grommet until they failed.

Boot Lace Samples

The construction of the shoe laces varied. Several, including diamondlace™, were solid braid.

Several were hollow braid sheath, with or without core. Several were flat braid. The ProCare Kevlar lace comprised a polyester hollow-braid sheath and a solid-braid multi-color polyester core. I detected no Kevlar yarn in this product.

The gold Kevlar was a flat-braid construction of Kevlar strands. The black and gold Kevlar was a flat-braid construction comprised of two gold Kevlar strands and many black polyester strands.

Test Procedure

The tests were conducted on a modification of the 4-station yarn-on-yarn abrasion test machine. That test machine is usually used to conduct yarn-on-yarn abrasion tests in accordance with industry standards. 2 3 The modified test machine is shown in Figure 10. 1/4 inch brass grommets, similar to those used in boots, were inserted in holes drilled through aluminium angle bars. These bars were mounted on the four stations of the test machine. The boot lace specimens was run through the brass grommet. Figures 11 and 12 shows a boot lace running through a grommet. The boot lace specimen was pulled back and forth through the grommet with a stroke of 2 inches at a rate of one cycle per second. Cycles were counted. Each counter shut off automatically when the lace failed.

Test Results

Graphs 1 and 2 compare the test results. The cycles to failure are averages for at least four tests on each sample.

The Diamond Lace boot lace lasted an average of 202,000 cycles, more than ten times longer than most of the other boot laces.

The Kevlar boot laces did not perform as well as the conventional boot laces. The gold Kevlar performed the best in this category, achieving an average of 9,500 cycles. The black and gold Kevlar boot lace, which contained only a few strands of Kevlar, lasted about two thirds the number of cycles as the gold boot lace which was all Kevlar.

The polyester boot lace performed best among the conventional boot laces, achieving an average of 38,800 cycles. Although the ProCare boot lace was claimed to contain Kevlar, it was all polyester, and did not perform as well as the other polyester boot lace. The leather boot lace performed the poorest, lasting an average of only 2,100 cycles.

The principal cause of failure of the boot laces in these tests was internal abrasion, caused by rubbing between strands as the boot lace bent and then unbent as it was pulled through the grommet. This is a common form of failure in cordage products.

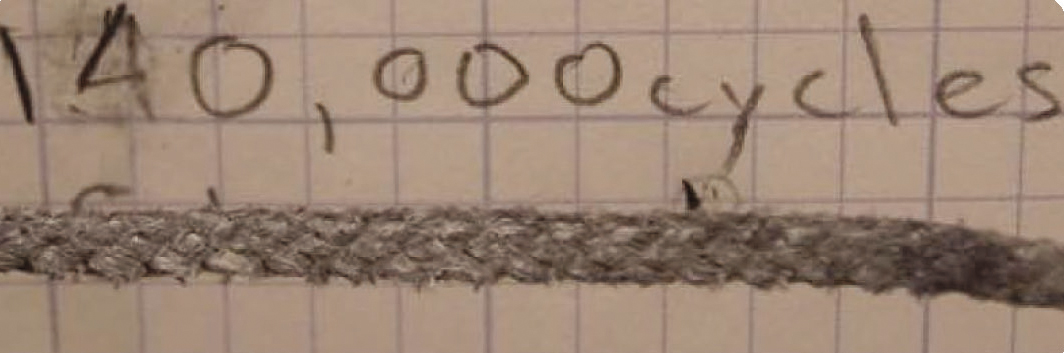

Kevlar is particularly poor in strand-on-strand abrasion of this type. Polyester is relatively good. Photos 12A and 12B show the Diamond Lace boot lace at two stages of testing. At 140,000 cycles, there was only modest abrasion. At 280,000 cycles, there was extensive abrasion, the boot lace was still usable, and it failed shortly after.

Many of the other boot laces suffered extensive abrasion long before complete failure, to the extend that they would be virtually unusable. Several of the boot laces essentially failed when their outer covers completely failed, even though the inner core remained intact. Photo 13 shows the ProCare Kevlar boot lace with the outer cover failed.

Conclusions

diamondlace™ boot lace performs ten times or more better than most other boot laces when pulled back and forth through a boot grommet.

It performed more than twenty times better than the Kevlar boot laces which were tested. The Kevlar boot laces did not perform as well as most of the conventional boot laces which were tested.

- DiamondLace

- ProCare Hiker Kevlar

- Bull Dog Kevlar

- Gold Kevlar

- Black & Gold Kevlar

- Polyester

- Covington

- Kiwi

- Leather

Materials Diamond Performance Fiber

Source Diamond Performance Ltd

Materials Polyester sheath, Polyester core, (no Kevlar)

Source Timberline

Materials Kevlar

Source Hank’s

Materials Kevlar

Source Duluth, ShoeLacesExpress.com, Gemplers

Materials Kevlar and polyester

Source ShoeLacesExpress.com

Materials Polyester

Source Local shoe store Morris Plains, NJ

Materials Polyester sheath, cotton core

Source Sears

Materials Polyester sheath, polypropylene core

Source Target

Materials Leather

Source Various